GMP POD Semi Automatic Roll Laminators (Korea)

GMP POD Semi Automatic Roll Laminators (Korea)

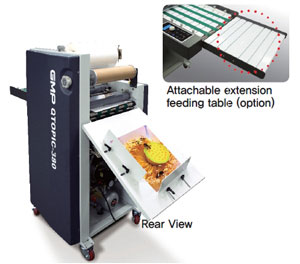

QTOPIC Series

- Qtopic-380

Perfect & Easy Operation for Digital Printing On Demand Solution

SPECIAL FEATURES

- Using household power supply (220~240V)

- Environmentally-friendly Thermalami® system

- Perfect lamination for wide range of Lamination

- POLYNEX(BOPP base) film

- NYLONEX(NYLON base) film

- PERFEX(PET base) film - Space-effective compact design for office, copy shop & photo shop

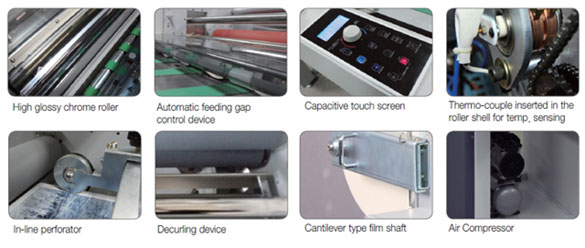

- Automatic paper feeding gap control system and automatic burst cutting system

- Film tension control device and decurling device are equipped

- Capacitive touch screen

- Sleeking solution & MICRONEX lamination with re-winder unit

- Gloss, Matt, Hologram, Metallic sleeking film

- MICRONEX(overlay coating) laminating film - Air compressor included

FEATURES

- Exchangeable/Commonized PCB

- Automatic feeding paper gap control

- Air compressor (with light weight & lower noise) is placed inside the body

- Strengthened laminating pressure for more stepped-up bonding power effecting perfect quality of output

- Ergonomic touch screen for enhancing operator-centric convenient control & quality productivity

- Cantilever type film shaft for easy film loading

APPLICATION

- Poster, pop sign, menu

- Book cover & jacket

- Photo graph & album

- Name card

- Gift certificate

- Label (Micronex Lamination)

- Greeting Cards / Year book

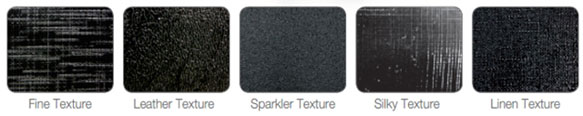

Basic patterns of embossing roller (option)

SPECIFICATION

| QTOPIC-380 | |

| Dimension (W*L*H, mm) | 720*1700*1350mm |

| Laminating speed | 1.5m/min ~ 10m/min |

| Paper size (W*L, mm) | Max : 380*500mm (option: 1200mm) |

| Min : 180*210mm | |

| Laminating films | Single Side: POLYNEX (20~43mic), |

| PERFEX(25mic), NYLONEX(27~44mic) | |

| MICRONEX (6~10mic) : Gloss, Matt, Hologram | |

| Sleeking | Gloss, Matt, Hologram, Metallic |

| Substrate thickness | 120 ~ 350g/m2 |

| Front roller diameter | Top: high glossy chrome ∅100 |

| Bottom: silicon ∅80 | |

| Rear roller diameter | silicon ∅55 |

| Power requirement | AC 220~240V, 50/60Hz, 12A |

| Power consumption | 2.8kw |

| Warm-up time | 5 min. |

| Heating system | INFRARED HEATER |

| Laminating temp. | MAX.150 |

| Temp. control | Capacitive Touch Screen |

| Speed control | Capacitive Touch Screen |

| Display system | LCD Panel |

| Roller pressure | Pneumatic Cylinder |

| Film core size | 77mm (3”) / Dual - 58mm, 50mm |

| Air Compressor | 1 HP, 89L/min |

| Temp. Sensing method | Thermo-couple inserted in the roller shell |

| Net Weight | 187 kg |